Crane is used for moving, lifting, raising, and lowering heavy objects. It has become the essential machinery in many industries, such as transportation, shipbuilding, aviation, automotive, and especially construction.

There are many types of cranes. However, the Electric Overhead Traveling (EOT) crane is the most popular one. It is suitable for daily weight lifting activities and requires less maintenance. EOT crane has many types from which we will discuss the difference between two cranes: jib crane and gantry crane.

The difference in design

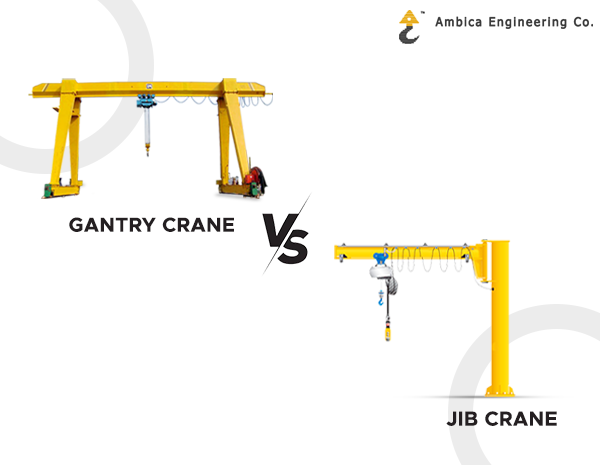

The design is the first and foremost difference between the jib crane and the gantry crane. A gantry crane has two points of ends or supports with a horizontal I-beam in between the supports. These points of ends are usually on wheels so that the crane or the loads through the crane can be shifted to different locations. However, a jib crane has a single point of contact through which it is managed. It is usually fixed to the ground or wall. But it also comes as a portable crane.

The difference in movement

The gantry crane is used for moving weight in a straight line with the horizontal I-beam with the help of a chain house and trolley. The jib crane is also for lifting or moving weight. However, it must be portable to function the same as a gantry crane. If the jib crane is mounted in-ground, distance becomes a limitation.

The difference in usage

The gantry crane is used for a heavyweight that has to be moved to a distant location. They are mostly required in factories, power plants, seaports, and similar workspaces. Jib cranes are generally used for small weights to a shorter distance. They are suitable for tight workspaces. Additionally, jib cranes have the capacity to lift loads from the ground to higher locations like roofs. It can also be rotated from 180 to 360 degrees.

In a nutshell, the gantry crane and jib crane both are suitable for different purposes. You need to set your requirement and purchase the crane from a crane manufacturer in India.