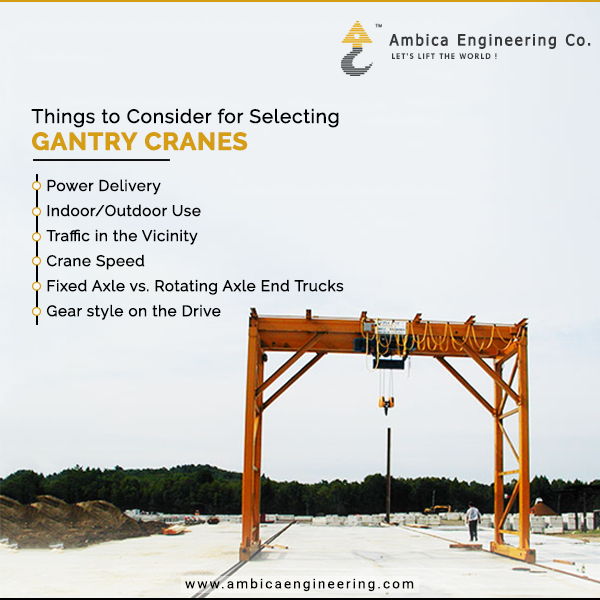

Though a gantry crane is flexible in its design and does not rely on building supports and can be made to be mobile, there are some aspects that need to be considered before getting a gantry crane from a crane company in Ahmedabad for your premises:

Power Delivery

For bigger outdoor gantry systems, a cable reel is a standard option for supply it with electricity. Cable reels use a design that’s either spring-loaded or motor-driven for releasing, retrieving, and storing the conductor cable for crane equipment. They can be placed as stationary or mounted on a swivel base to enable the cable to payout in different angles and directions.

Indoor/Outdoor Use

If the gantry crane will be operating outdoors than it becomes vital to consider the right material for the crane as well as applying appropriate paint on it to protect it from the harshness of the environment. As the crane will be used outdoors, materials like stainless steel or galvanized steel are more preferred as they can stand corrosion and have much resistance towards the effect of UV exposure, saline water, humidity, and extreme temperatures.

Traffic in the vicinity

Gantry cranes are much preferred in areas where there is a lot of traffic and other moving vehicles like carts and forklifts. Larger gantry system can let forklifts in to take up materials and also allow enough space to bring inside the trucks for loading and unloading

It is essential to consider the type of equipment or personnel that will be operating nearby the gantry as it is vital to be aware of any possible obstructions that the crane can have.

Crane Speed

Gantry cranes are most suitable in situations where the speed is not a priority. Unlike bridge cranes, the load on gantry cranes is generally moved at a slower crawling speed.

Fixed Axle vs. Rotating Axle End Trucks

For using outside, it is better to go for rotating axle end trucks as they are designed to be comparatively more robust and heavy duty. They also include fewer parts, thus reducing the maintenance cost.

Gear style on the Drive

A helical or bevel gear drive is more beneficial in comparison to a worm gear drive. A helical or bevel gear drive can roll back on itself in the case it sustains an impact hence causing less pressure on the gears themselves. But on a worm gear drive, the gears can break apart in the on condition suffering an impact because they aren’t created to work in reverse.